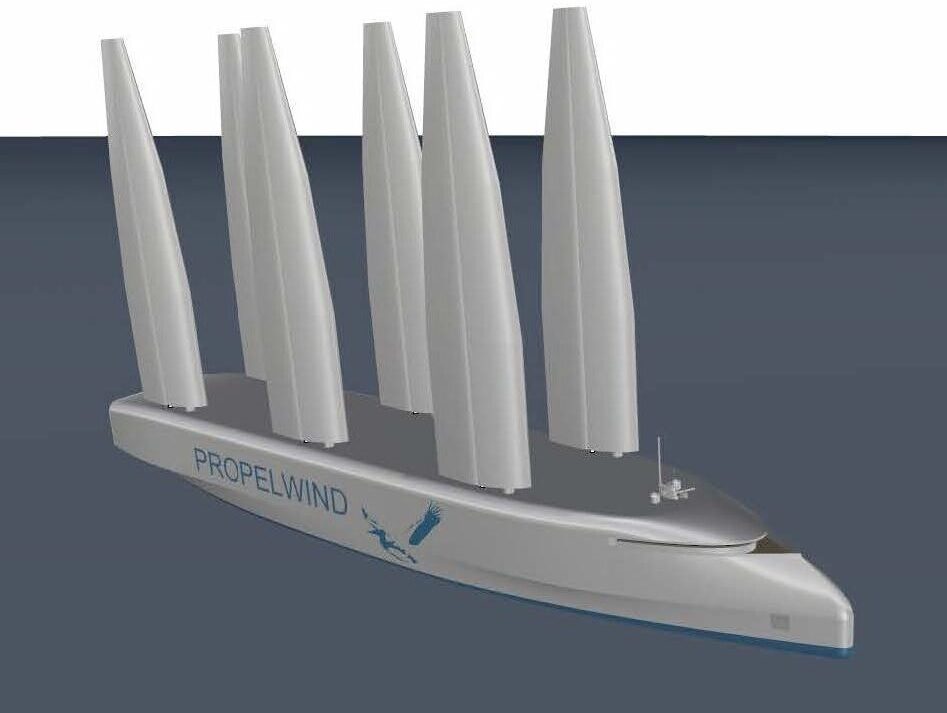

MONOHULL

A real wind propelled cargo vessel ready for absolute zero-emission

Main Principles

- generic hull for different light cargo’s

- aerodynamic performance: rigid articulated wingsails, flush deck, rounded sheer strake

- hydrodynamic efficiency: very low block coefficient, wave piercing bow

- real wind for main propulsion: use of wind only during at least 85% of the time (average) on many trading routes

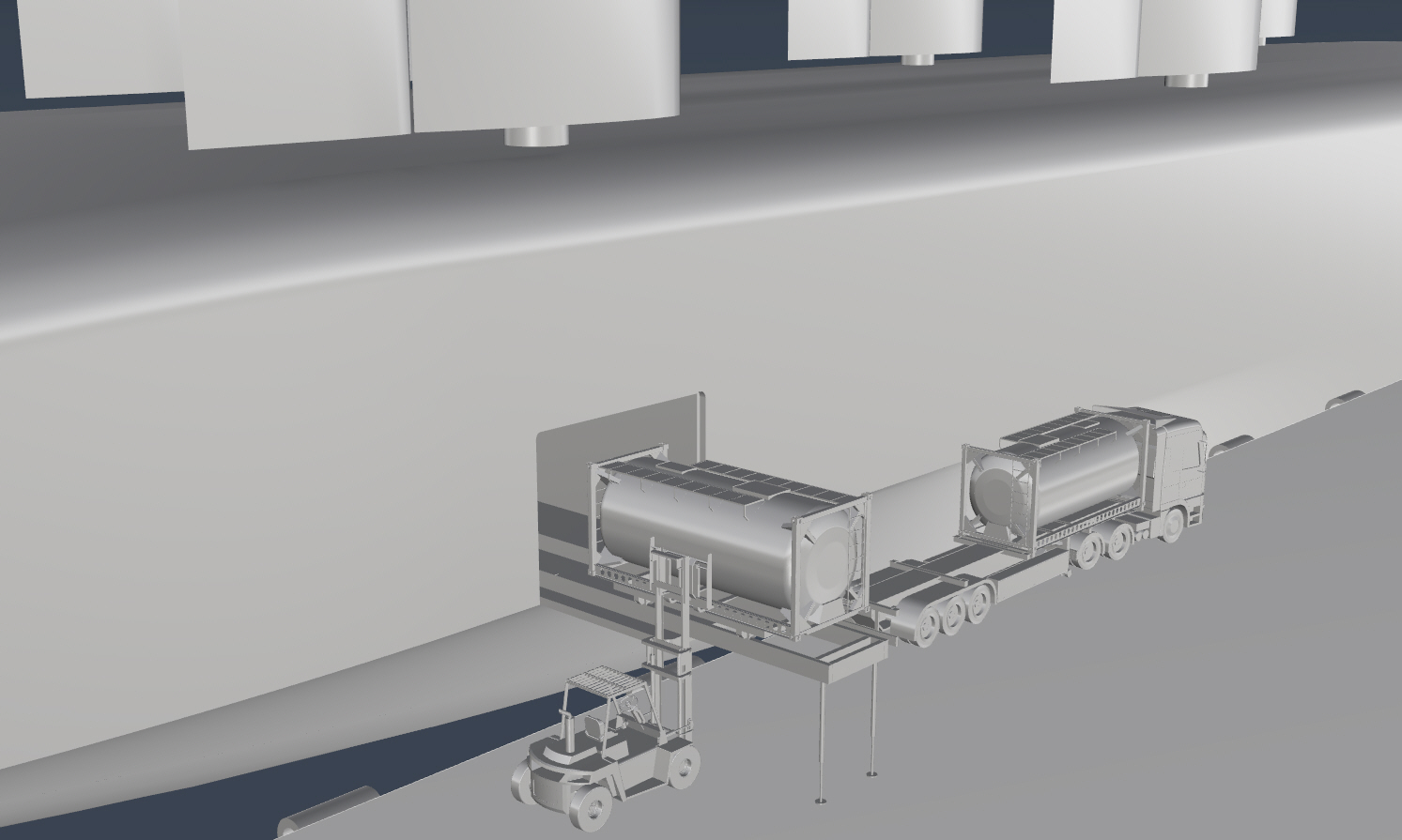

Zero-Emissions Within Reach

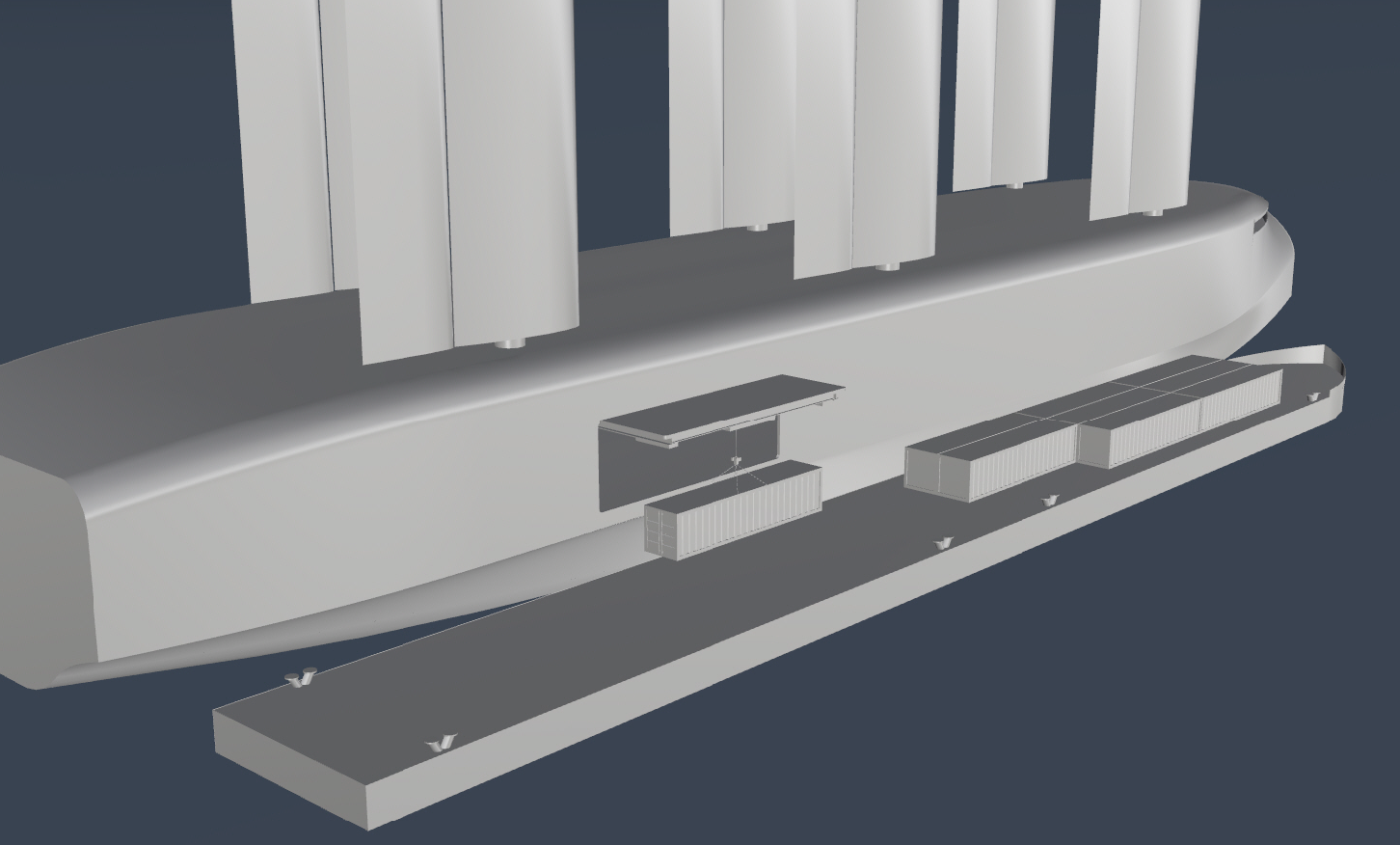

Thanks to the extensive use of wind, the quantity of green fuel required on board for assistance is reduced to the content of a few ISOtainers (20 – 40 – 45 ft) to be brought to the ship by truck. No need to wait for the expensive green fuel supply chains and bunkering systems, anyhow unavailable for the next decade.

The loading of green fuel ISOtainers uses a unique rails & trolley system, permanently fitted on board and deployed at quayside. The only external equipment required is a forklift. No wire-based winch is needed to handle an ISOtainer, virtually eliminating the risk of falling.

The above “absolute zero-emissions” (AZEM) feature can easily be retrofitted on the wind-propelled vessel described below. All the works can be carried out alongside in a harbor, with prefabricated structural components, hull outfitting items and machinery components and piping.

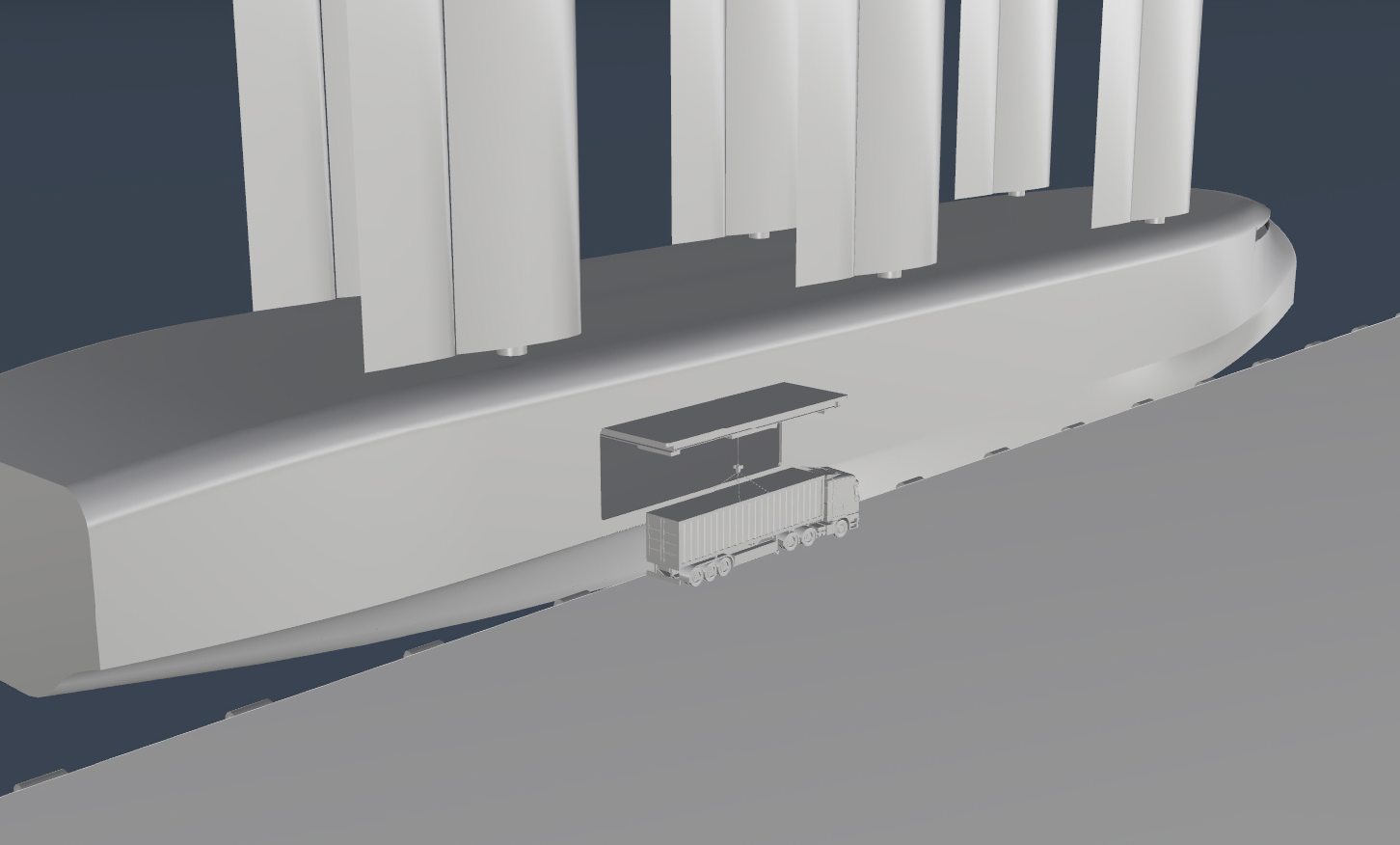

Agile, Ultra-Green Container Vessel

The initial container vessel concept, 250 TEU@12t (LOA 140.0m) should be launched early 2026 ; it has been evaluated by routing on several trading routes:

- average speed: 12 kts

- resulting carbon footprint per TEU smaller by a factor than the footprint with a large container vessel trading at eco-speed.

The concept will be scaled up to 600 TEU, the real size for series construction, after one full year in commercial operation by series of 250 TEU vessels.

In addition:

- the fully enclosed containers storage provides a unique cargo protection: no risk of falling overboard, quick and effective active fire protection, no exposure to bad weather;

- the vessels will be fitted with a unique lateral container self loading / unloading system (patented), allowing to handle containers directly to / from the trucks on quayside, or to / from an inland waterways vessel moored alongside.

This offers the possibility to avoid the large container terminals, potentially congested, and bring the cargo closer to the end user, limiting the road transportation and enhancing further the decarbonization of the supply chain.

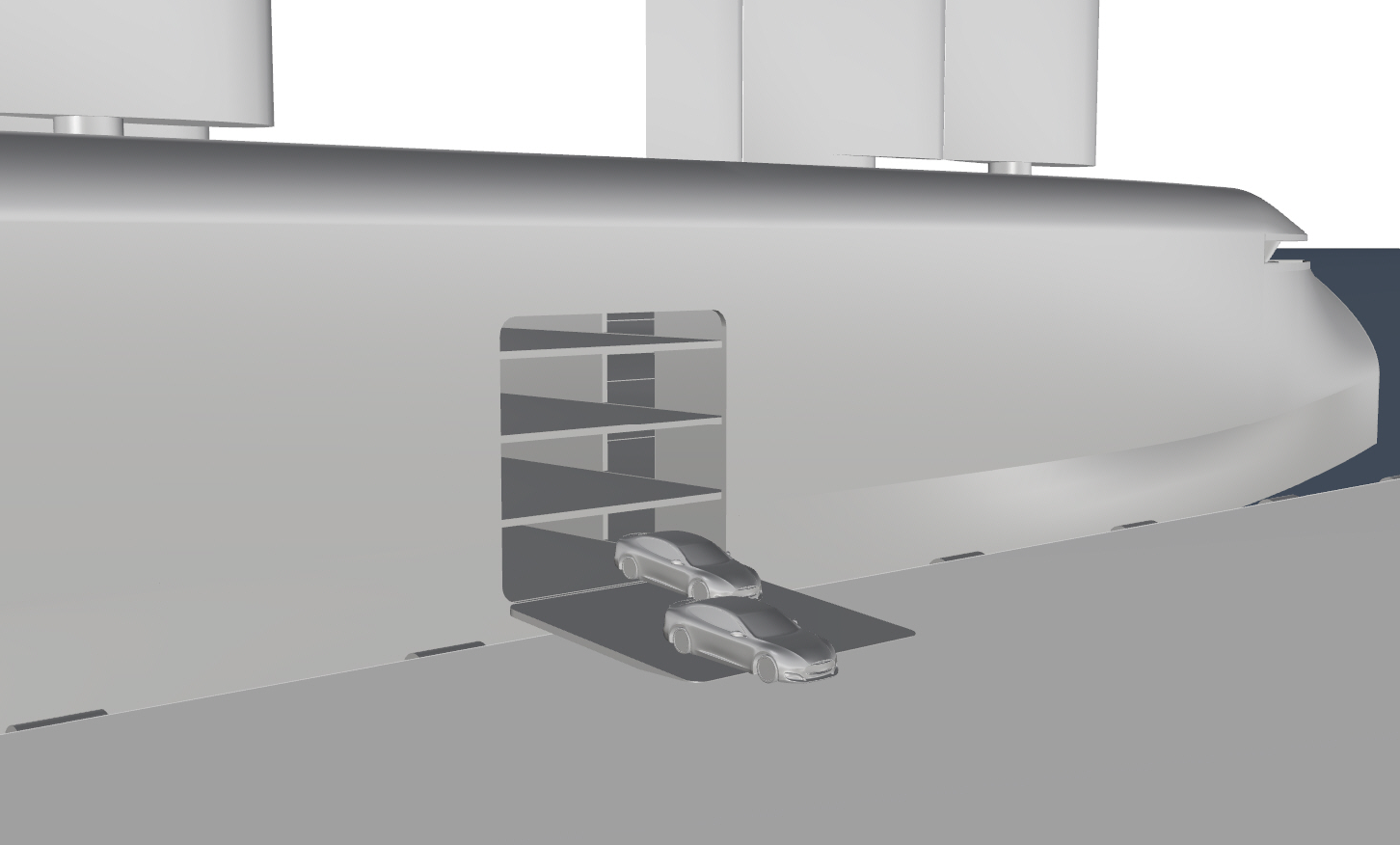

Smart, Ultra-Green, Fire-Safe EV Car Carrier

A pure car carrier version of the generic PROPELWIND concept is being designed, initially for 600 EV’s to be loaded in 12 fire-separated compartments, aiming at maximizing the passive and active fire protections.

Loading – unloading operations are foreseen through :

- large midship lateral doors – portside and starboard, to be used as access ramp

- an internal access trunk instead of the aft door, with a lay-out similar to a land-based parking

Above features will facilitate the use of smaller harbours.